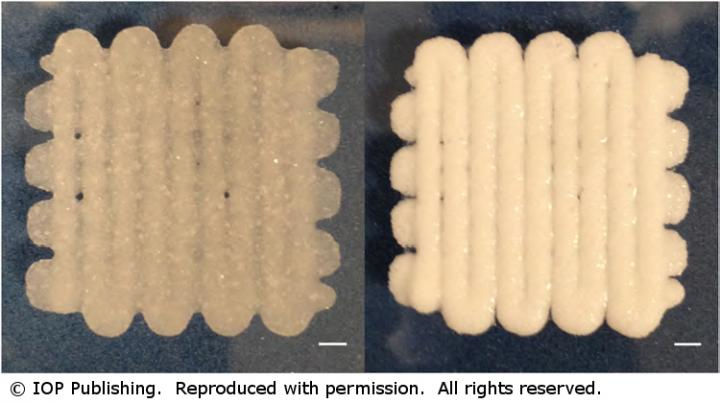

用生物打印产生的结构,使用了悬浮在水基载体里的微颗粒。图像显示了结构固化前后(24h)。比例尺是2mm。

图片来源:IOP出版社。

科学家已经开发出一种新技术,能在常温下生物打印一种类似“橡皮泥”的坚固膏体,这种膏体能够结合释放蛋白的微球。

科学家们表明这种生物打印材料是微粒膏体的形式,可以经由注射器注入,能维持类似于松质骨的应力和应变——松质骨是通常在长骨端部见到的“海绵”骨组织。

这项工作7月3日公布在杂志《生物制造》上,表明环境温度下的生物印刷是一个可行的途径用来生产骨修复材料,这些材料能包含细胞和蛋白质,可以加速大型骨折的愈合。

“生物印刷是组织工程的热点研究领域,” 论文主要作者诺丁汉大学的杨静(音译)博士解释说,“然而,通常它需要的打印环境和活细胞并不相容——而那些与活细胞相容的材料通常又不具有足够的机械性能用于某些应用。”

“最初我们把这一材料的临床应用瞄准了注射用骨缺损填充物,”杨博士继续道,“但我们推测,它的性能会使得它非常适合作为支架来重建更大的形状,这将有助于更复杂的重建,如鼻再造。”

通常情况下,生物印刷技术涉及高温处理,或者施加紫外线或有机溶剂,所有这些都阻止了在制造过程中加入细胞和治疗性生物分子。

这种技术涉及了在室温下用载流体混合聚(L-乳酸-共-乙醇酸)和聚乙二醇,以形成一种带微颗粒的可挤出膏体,以被制成所需的形状。这种膏体在37℃下培养形成多孔的固体结构。这个过程的下一步将是在临床应用中应用该方法。(生物谷Bioon.com)

信源:eurekalert

生物谷推荐的英文文献:

Cell and protein compatible 3D bioprinting of mechanically strong constructs for bone repair

doi:10.1088/1758-5090/7/3/035004

Rapid prototyping of bone tissue engineering constructs often utilizes elevated temperatures, organic solvents and/or UV light for materials processing. These harsh conditions may prevent the incorporation of cells and therapeutic proteins in the fabrication processes. Here we developed a method for using bioprinting to produce constructs from a thermoresponsive microparticulate material based on poly(lactic-co-glycolic acid) at ambient conditions. These constructs could be engineered with yield stresses of up to 1.22 MPa and Young's moduli of up to 57.3 MPa which are within the range of properties of human cancellous bone. Further study showed that protein-releasing microspheres could be incorporated into the bioprinted constructs. The release of the model protein lysozyme from bioprinted constructs was sustainted for a period of 15 days and a high degree of protein activity could be measured up to day 9. This work suggests that bioprinting is a viable route to the production of mechanically strong constructs for bone repair under mild conditions which allow the inclusion of viable cells and active proteins.